hehe, yeah right. i'm a mil spec certified assembler, and i can tell you we didn't even have tools like that on our iso 9001 manufacturing line. you think a normal person would?

+ Reply to Thread

Results 31 to 36 of 36

-

-

I work in Aerospace sector, and our primary soldering irons are the expensive Metcal, and they are guaranteed to be within +/-2 degree F.Originally Posted by minidv2dvd

The cheaper Weller soldering iron shown in the picture is used for non-critical stuff. Since Weller's temperature will drift as it gets old. We end up need to check it with its temperature readout. It is normally set between 685 and 700 degree F.

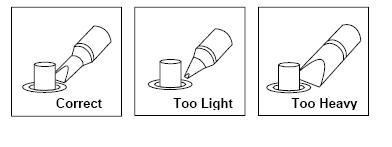

The important thing about properly solder in an item like projection lamp is the size of the tip. Use a few different tips to get the soldering done, will save you a lot of grief later.

-

I 've changed many bulbs in high powered projectors at work.

(mostly 600-800w Xenon arc projectors )

All of them have had crimp connectors for the wire leads.

They get very hot & FWIW I doubt solder would be a good choice.Losing one's sense of humor....

is nothing to laugh at. -

@mikel - so maybe that wouldn't work at all then?

Honestly like I've said I've never really soldered anything anyway - just curious if it would be worth attempting.Donatello - The Shredder? Michelangelo - Maybe all that hardware is for making coleslaw? -

Hard to say.

It would probably depend on how close the connection was to the bulb.

The bulbs that I've delt with run VERY hot, and I think would easily

melt solder that was nearby.Losing one's sense of humor....

is nothing to laugh at. -

You don't want soft solder anywhere near a high-powered lamp. Anything near the socket should be spot-welded, or mechanically very secure (good crimping or tight screws). Make sure insulation is appropriate for the temperature. Teflon is good, glass braid better. I like to scrounge prebuilt connector assemblies. Keep soldered connections out of the high-temperature zone - otherwise they will come back to haunt you. Ceramic wire nuts - the white ones - work well at extreme temperatures.

Similar Threads

-

new HD projector

By mgrig in forum Newbie / General discussionsReplies: 2Last Post: 23rd Apr 2010, 14:01 -

Interference from Incandescent heat lamp

By Bshanahan in forum Capturing and VCRReplies: 6Last Post: 19th Feb 2010, 15:37 -

Is it safe to sell our free cell-phones? Also, is it safe to BUY?

By siratfus in forum Off topicReplies: 3Last Post: 12th Dec 2009, 16:30 -

more lamp time on my PT-AE900U

By ratboys in forum Newbie / General discussionsReplies: 0Last Post: 24th Jun 2009, 23:40 -

PS3 and my Projector not getting along.

By StoneColdWhat in forum DVB / IPTVReplies: 7Last Post: 16th Feb 2008, 19:00

Quote

Quote