I'm saying that it is the disk. I still think that many of the printable disk are really meant for hot wire thermal transfer, not inkjet!

And foo, the ink is drawn from the suction created within the cartridge. It can be a delicate balancing act between the ink height and the printhead height. Too low and you get crappy output. too high and the inks seeps out of the cartridge when it is idle. When you get it right with the modern printers, it works great. The older one are a little more difficult. The tubing doesn't get tangled the same way the control cables for the head do not get tangled. For the one that I made, I attached the tubing to the ribbon cable for the head. Works great. The one I bought, they attch a piece of plastic across the opening where you can see the print head as it scans acroos the paper. Very crude, but it works. It is best if you buy tubing that is connected to the adjacent tubes so it forms a ribbon. If no you need to attach the single tubes to each other or some other support. I'll take a picture of the 2 a little later to show everyone.

+ Reply to Thread

Results 91 to 120 of 130

-

Hope is the trap the world sets for you every night when you go to sleep and the only reason you have to get up in the morning is the hope that this day, things will get better... But they never do, do they?

-

Are you using 4x BeAlls? The surface is smooth or like plain paper?Originally Posted by tonyk23

If you find a better option please share, I'll order 4X printable BeAll as soon as they are back in stock. -

I just looked at your site. where did you get the twist lock connectors. They look expensive. You might try just a regular hose barb connector. Also if you get the type that has a #10/32 thread, you can drill and tap the plastic in the cart, and then thread the connector into the cart.Originally Posted by AlienRelics

The waste ink level in the Epson is computed by the number of time the printer sprays into the waste system. It simply counts the pulses that it uses during normal cleaning and printing (when it cleans). So somewhere there is a counter that will have to be reset.

You said you will be running an Epson 1520. I have a 1520 that I run with the Generations ink. It works very well as soon as you get the color profile set. I have also converted it to continuous inks. This is something I was told could not be done by someone at NOmoreCARTS.com. Needless to say, I didn't like the answer. The reason they said it could not be doen is that the 1520 does not have enough suction to draw the ink into the cart. This can be fixed by careful position of the bottles. Too high and it drips, too low and it will pull the ink back out of the heads when it is idle. This is bad because it causes a clog. It is also impossible because the switch that you must trigger to tell the printer a cart has been removed and replaced to reset the ink counter, can not be accessed. I simply cut 2 traces on the circuit board, soldered 3 wires to the board, and installed 2 normally closed switches. I also put a switch in for the cover open switch. Now when it runs out of ink, I push the cover switch, then the 2 switches to "remove the carts. Release the cart switches, then the cover switch, and the printer goes through the normal filling sequence. Works pretty well. Maybe you could put the info on your web page. I'm going to write up the info soon (with pictures) and put it into a PDF for another person who is looking into buying a 1520. Would you like this info when I'm done? It would be used in conjunction with a 6 disk caddy too, at least for him. For mew the 1520 will still be printing photos with the pigment inks.

Also I am using the G4 inks in it now. If ti wasn't so much work, I might use the G6 inks like I do in my 9500.Hope is the trap the world sets for you every night when you go to sleep and the only reason you have to get up in the morning is the hope that this day, things will get better... But they never do, do they? -

Got them from a surplus store called The Creation Station. Hard to describe... if some manufacturing plant has leftovers, they buy them for next to nothing and resell them for next to nothing. I have more so I'll probably use those twistlocks when I convert the Epson 1520.Originally Posted by The village idiot

One of the things I really like about Canon printers.... they have an optical ink sensor. On the 6000 it is a little triangle on the bottom of the ink tank (which is clear) and a sensor shines up inside. When ink covers it, just like a prism under water the light is not reflected back. As it is uncovered, of course, light is reflected back and it even gives a quantitative rough measure when it is getting low vs when it is out.Originally Posted by The village idiot

Yes, yes! To all of the above. I also read on at least a couple of sites about the 1520 and bulk, and had the same thoughts exactly. I would love to put up a page with your info on it!Originally Posted by The village idiot

Have you found that you need to adjust the bottles as the ink runs down, or just keep them topped off, or is it not quite that critical?

The bottles I picked up at Creation Station for ink are 60mL but are rather tall, so I may find the height change with use to be a problem with the 1520. I have no idea how the Canon 6000 or 5100 will fare. Certainly the ink height changes by only about 1 inch, and I've been able to get the Canons to suck that sponge pretty dry of ink.

Steve -

I'll have to check, but I don't think the 1520 has enough room to clear something that tall. I put angles on mine and it seems to work. I'll get working on that soon, and put it all in a PDF. The levels of the ink are very critical in the 1520, I set mine up so that I only put about 2 ounces of ink in the bottles at a time. I also angled the bottles so that there was less of a height change. Total mine changes about .5 to maybe .75 inches. I found that raising or lowing the bottles by about that much made the system work, or not work correctly. It will suck the ink over a fairly wide range, but then when it is idle it will cause problems. The biggest problem is if the ink is too low. Then it can sometimes pull an air buble into the printhead! Not a good thing.

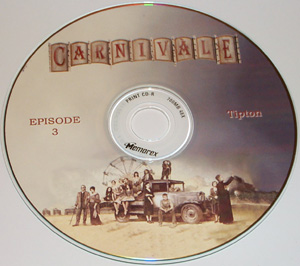

And as long as I am here, I just finished printing some disks with the Lexmark mod. 3 for 3 are great! Here's what it looked like (note the color shift is from the camera, not the disk. The printed disks looks very close to the original artwork!) These are the Memorex inkjet disks, and they were dry to the touch when they came out of the printer! This is no lie, all I had to do was run a towel around the edges to get the ink that is out side the coated area, and I was done! Can not complain for what it cost, even with the missing color cartridge I had to buy!

Here's what it looked like (note the color shift is from the camera, not the disk. The printed disks looks very close to the original artwork!) These are the Memorex inkjet disks, and they were dry to the touch when they came out of the printer! This is no lie, all I had to do was run a towel around the edges to get the ink that is out side the coated area, and I was done! Can not complain for what it cost, even with the missing color cartridge I had to buy!

Settings were BEST quality and PHOTO/GLOSSY paper in the Lexmark interface. For a cheap POS printer, it certainly did a good job.Hope is the trap the world sets for you every night when you go to sleep and the only reason you have to get up in the morning is the hope that this day, things will get better... But they never do, do they? -

By "clear something that tall" do you mean the twistlocks? I was going to remove the cover and cut out part of the top to fit the bulk feed, anyway. Otherwise I will have to get some brass tube and curve it, and epoxy them in.

Very nice prints! The Memorex are the ones I plan on using. Did some research, as far as I can tell they should last a long time.

I've got some CDR's here that are already to the point where some readers can't read them. Need to get them all copied off onto new CDRs. Years of graphics work could be lost.

Steve -

Just bought the Epson 900 and found this thread pretty helpful. I tried printing on my DupeZ DVD media (not listed as inkjet printable) and things didn't come out so well. I am getting ready to order some printable DVD media and wanted to know if anyone has anymore input on what works best.

It looks like people have had success with the BeAll DVDs. Any more comments on those or any other media? -

If you have a CompUSA near you, they now stock the Memorex inkjet printable CD-Rs, just in case you want something for testing.

Hope is the trap the world sets for you every night when you go to sleep and the only reason you have to get up in the morning is the hope that this day, things will get better... But they never do, do they? -

Yes! I just noticed that, too, about CompUSA carrying the Memorex inkjet printable CDs.

Did you ever get a chance to finish that PDF?

It's funny about the 1520 as it has exactly the same printhead as the Epson Color 800 and 3000. Based on that, and your experiences with a 1520 and bulk, I'd guess that it is not the suction that is a problem, it is an inadequate seal on the parking pads.

Steve -

Sorry, never did do anything with that project, got too many others in the works, and just haven't done anything yet.

You're right that the heads seem to be enough, the heads always come uo as either 800 or 1270, never seen them cross to the 3000. I've considered changes from the carts as a buffer to the real ink buffer used in the 9000 and other tube feed printers. It looks like they would offer much better flow, and they will fit in the head. They are also only about $9.00 each or less, need 4 of them and then a way to hold them in the printhead, also need to defeat the cartridge installed sensor with a switch wired to the mainboard. Short pin 1 of each IFL cable to ground for cart installed, open from cart removed. There are 2 test points you can solder the wires to, if you are careful. Could also use the ink buffers from the 3000 since they should fit too.Hope is the trap the world sets for you every night when you go to sleep and the only reason you have to get up in the morning is the hope that this day, things will get better... But they never do, do they? -

Has anyone tried these?

Taiyo Yuden 4X DVD-R 4.7GB Blank Disc for General Purpose

Silver Ink Jet Printable!

http://www.meritline.com/taiyo-4x-dvd-r-dvdr-media-silver.html

They appear to be silver top instead of white. IMO, the silver top CDRs look much better than the white. They have sheen to them, not glossy and not matte.

I am using a an A105 burner.

Richard -

I was wondering if anyone knows how to position an image in Photoshop to get it to print on center with the Epson 900. It seems like I lose quality when I bring in images to Epson Print CD.

-

WECARE has something called "Print-Fix", it puts a transperant coating

on your print, it also has a positive effect on the contrast, and has also

a protective effect in, that it filters the UV slightly.

I like this product, also because it's the only one i can get...Thanks,

Yodel -

I am looking for the same thing. I notice a large quality drop myself. Plus it would just be quicker to print from photoshop since this is where i create the image from. If i can'Originally Posted by FernE97

t find one soon, i just might make my own. I will let you know. -

I wished it was that easy too... But i guess there's also a matter ofOriginally Posted by stangyamahar1

positioning between software, and the position of the cd tray,

otherwise you have to put the tray in at the same position, every time to

get the same result(s)Thanks,

Yodel -

Well I made a template for a cd that is 118mm x 118mm and I was thinking I could just adjust the print position in photoshop but it would probably be easier to get a template that would be the size of the cd tray.

-

I also tried making a photoshop template, by scanning the CD Tray. I was able to get the horizontal alignment right, but it's next to impossible to get the vertical alignment perfect.

-

I guess making a numberd grid, printing this on a "dud" printable cd/dvd,

would tell something of the position, and IF this grid is always at the same

position printed, you can position the center of the circle(s) i guess.Thanks,

Yodel -

I actually made one yesterday. It was not that hard really. I simply measured the tray and created a new document with the corresponding measurements. It will allow you to print with any selections paper, glossy, dvd/cd etc. but i did notice that dvd-cd seems to align the best, as the printer actually reads the tray and does minor adjustments.

It took me a few hours of tweaking and test printing, but i got it. I made the template for Ritek G03 inkjet printable dvd-rs as well as for the Ritek inkjet printable cd-rs. I will upload it and post a link here soon.

I used the CD/DVD setting, best photo, epson vivid color, and saturation +2. The quality definately seems better than the epson software.

I will be making a template for my memorex, as well as the Beall also. Although the memorex is pretty close to the size of the ritek dvd. But i definately want a beall for up to the hub printing. -

Ok so here it is. I have four folders on the document.

Memorex CD

Ritek DVD

Ritek CD

BeAll DVD

Enjoy, and let me know what your experience is with it. I have already used it on about 30 discs, and it is lining up perfectly. I did create these tempaltes with about a 1/2' mm bleed area on the inside and outside, which will help to alleviate any alignment issues when printing a full color disk with edge to edge prints.

http://www.ryangreene.net/covers/900template.zip -

Do you also line up the rubber rollers with the ones drawn on the Epson 900 cd-tray ?

Thanks,

Yodel -

Yes, line up the rollers just as you would with the epson cd software.Originally Posted by yodel

-

Only can't get the template working in PaintShop8, haven't PhotoShop,Originally Posted by stangyamahar1

guess i have to make a square of 12cm template with the correct position... or has somebody already done this ?Thanks,

Yodel -

Ok, so i just backed_up TombRaider and thought i would show you a comparison.

The first pic is the original tombraider DVD. Not that great, i like mine better! Second pic is the printed DVD with my own custom graphics on a ritek g03 disc using my Photoshop template. The third is the actual graphics i created to print on my disc. You can use this for comparison. I must say, using photoshop for creating and printing has sped things up, and really produces far better prints.

Second pic is the printed DVD with my own custom graphics on a ritek g03 disc using my Photoshop template. The third is the actual graphics i created to print on my disc. You can use this for comparison. I must say, using photoshop for creating and printing has sped things up, and really produces far better prints.

Enjoy!

Original DVD

Ritek G03

Original Art I created and printed in photoshop

-

wow... nice work stangy. What resolution are the pics that you use to make your discs?

-

Thanks. I always try to use the highest rez pics i can find. Most are usually around 250-350 dpi. Unfortunately for lots of my older movies it is hard to find good high rez scans of posters and such.

those tomraider pics were all around 240 dpi. Thats about lowest i like to go, although a moderate amount of resizing is possible with the right techniques. Believe it or not i put that little picture together in about 15 minutes. It took me longer to find the pics than it did to create it. Most of the time 5-10minutes was spent on isolating the hanging laura croft image.

Believe it or not i put that little picture together in about 15 minutes. It took me longer to find the pics than it did to create it. Most of the time 5-10minutes was spent on isolating the hanging laura croft image.

I just kind of threw on the generic logos to keep it looking a little more authentic. I try not to put too many though, as i usually like to keep nice pics on the disc, rather than type. -

Do you find your graphics online? I have a hard time finding pics that are high res enough to use for cds and covers. The only suitable place i've found is dvdcoverart.com, but whenever i google search for images, i rarely find what i'm looking for.

-

Yeah, i find most of them online. I post on dvdcoverart also. I have covers that i have uploaded there. I go by graphicdesigner77 on that site. Actually i go by that name on most sites, but for some reason i didn't here? Maybe i will see if i can change it.Originally Posted by vandakeg

-

Thanks for the templates Stangy, just what I was looking for

I'll let you know how they worked for me once I print some.

I'll let you know how they worked for me once I print some.

-

Do you guys have any tips for PaintShop (Jasc) users, users who are n't so fortunate to own a pricey PhotoShop (Adobe)

Thanks,

Thanks,

Yodel

Similar Threads

-

Epson Generic Printer Ink - Here I Go Again!

By leebo in forum MediaReplies: 12Last Post: 29th Apr 2011, 16:28 -

Epson R260 Generic ink?

By jayndenver73 in forum MediaReplies: 48Last Post: 15th May 2010, 13:42 -

EPSON STYLUS PX710W all-in-one

By kyrcy in forum ComputerReplies: 2Last Post: 15th May 2010, 09:00 -

Epson R320 ink cartridge ordeal....

By rubberman in forum ComputerReplies: 6Last Post: 25th Aug 2009, 15:47 -

Ink question for refillable Epson R220 cartridges

By Mahime in forum MediaReplies: 3Last Post: 14th Jan 2008, 21:54

Quote

Quote